In the steel industry, we often hear the concept of hot rolling and cold rolling, so what are they?

The rolling of steel is mainly based on hot rolling, and cold rolling is mainly used for the production of small shapes and sheets.

The following is the common cold rolling and hot rolling of steel:

Wire: Diameter 5.5-40 mm, coil shape, all hot rolled material. After cold drawing, it is cold drawn.

Round steel: In addition to the precise size of the bright material is generally hot rolled, there are also forged (surface forging marks).

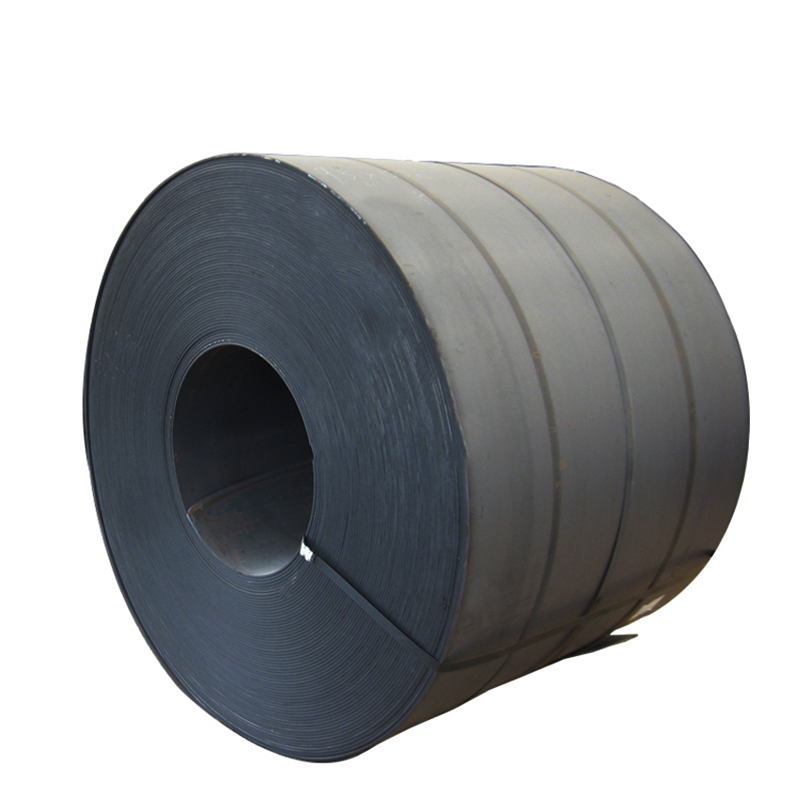

Strip steel: Both hot and cold rolling, cold rolling material is generally thinner.

Steel plate: cold-rolled plate is generally thin, such as automotive plate; There are more thick plates in hot rolling, with similar thickness to cold rolling, and the appearance is obviously different.

Angle steel: All hot rolled.

Steel pipe: welded hot rolled and cold drawn.

Channel and H-shaped steel: hot rolled.

Rebar: hot rolled material.

Hot rolling and cold rolling are the processes of steel plate or profile forming, which have a great impact on the structure and properties of steel.

The rolling of steel is mainly based on hot rolling, and cold rolling is usually only used for the production of precision steel such as small steel and sheet steel.

The termination temperature of hot rolling is generally 800 ~ 900 ° C, and then it is generally cooled in the air, so the hot rolling state is equivalent to normalizing treatment.

Most of the steel is rolled by hot rolling. The steel delivered in hot rolled state, due to high temperature, produces a layer of oxide sheet on the surface, so it has a certain corrosion resistance and can be stored in the open air.

However, this layer of oxide sheet also makes the surface of hot-rolled steel rough, the size fluctuation is large, so it requires smooth surface, accurate size, good mechanical properties of steel, to use hot-rolled semi-finished products or finished products as raw materials and then cold rolling production.

Advantages:

The molding speed is fast, the output is high, and the coating is not damaged, and it can be made into a variety of cross section forms to meet the needs of the use conditions; Cold rolling can produce great plastic deformation of steel, thus increasing the yield point of steel.

Post time: Sep-19-2023